With fulfilmenttools, REWE Group has a tech subsidiary that ensures that the goods are delivered to the customer from the warehouse or stationary shop after the online order has been placed. A task that only appears simple at first glance. In the background, this means providing customers with various delivery options and finding the optimal route for the goods for retailers.

The first day of the 2020 lockdown was the day Björn Dröschel received the keys to fulfilmenttools' new office in Cologne's Schanzenstraße. "And then I had to send our employees straight home again," says the Managing Director Product & Technology, recalling the date that heralded the start of everyday working life as it still is today.

The managing directors of fulfilmenttools: Jürgen Brock, Linda Kuhr and Björn Dröschel

The managing directors of fulfilmenttools: Jürgen Brock, Linda Kuhr and Björn Dröschel

That was almost exactly two years ago. Since then, fulfilmenttools has grown enormously and has created a positive corporate culture despite the difficult situation: "It takes an extra portion of motivation to build such a productive team in this time," says Linda Kuhr, who as Managing Director is responsible for Finance & Legal, People & Culture, Partner Management and Professional Services - about the company, which has now grown to over 50 employees. And the signs continue to point to growth.

But what exactly does fulfilmenttools do? And how does the company fit into the range of IT service providers that now complement REWE Group's portfolio with important components of online retail?

Put simply, fulfilment tools ensure that the goods are delivered from a shop, usually online, but also offline in a shop, to the customer. This can be done in various ways - for example from the warehouse or shop or via Click & Collect in the store. Same-day delivery is also an important topic for fulfilmenttools, particularly with regard to the food retail sector.

Fulfilmenttools also offers retailers returns processing or the option of reserving goods as a service. This is because the software - like Commercetools - has a modular design, meaning that it is set up for a wide range of sectors, from food to clothing or DIY.

In addition, fulfilmenttools can be used in the business-to-consumer and business-to-business sectors and for brands that sell directly (DTC) - regardless of whether they are large corporations or SMEs. "We are detached from the industry," emphasises CEO and Head of Marketing & Sales, Jürgen Brock. "Our argument is that with online grocery, we have understood the most difficult and complex industry and developed efficient solutions. This helps us to quickly understand other industries, even if they have different challenges."

First example: the traditional bakery "Peter's gute Backstube". The bakery approached the fulfilmenttools team at the beginning of the pandemic and asked for a Click & Collect solution. Since the number of customers was restricted indoors, long queues had formed outside the bakery's branches. Customers should therefore be able to pre-order goods online and collect them in-store without having to queue. During the pandemic, the bakery was therefore looking for an intuitive solution for its 55 shops that could be implemented quickly and connected to an existing online shop. fulfilmenttools impressed with its easy-to-understand user interface and fast implementation.

However, Click & Collect is just one component in the company's scope of services: "Our target vision is clearly omnichannel fulfilment - in other words, fulfilment concepts that combine bricks-and-mortar retail with the online shop. This also includes ship-from-store or the distributed order management system as the centrepiece, which uses intelligent logic to distribute orders from the online shop to the optimal fulfilment location," emphasises Linda Kuhr.

This also raises the question of where the goods are and how they can be delivered to the customer as quickly as possible And vice versa: if the customer returns a pair of trousers, fulfilmenttools wants to make it possible for the trousers to be returned to the shop that needs them most urgently and can sell them, thus eliminating the need for detours such as storage. This can save process steps.

But that would be the final step, says Björn Dröschel: "We don't need any information about where the goods are for our service. Our approach: Start simple, start easy, but start and learn from the process with the customer. The system learns and saves which items are available where. So you can start directly without any stock information. But of course, the more information we have, the faster we can fulfil the customer's request."

Based on this information, the retailer can also create rules themselves that determine how the goods are delivered to the customer. For example, it can be set up so that a certain stock level is always held in the shops and this is very precisely tailored to the individual shop. This prevents shelf gaps from occurring in the shops.

In addition to flexibility in delivery routes and stock levels, speed is a key issue in online retail - especially for food retailers.

Second example: the Polish convenience chain Zabka with its latest service Zabka Jush. The challenge here lies in so-called quick commerce, combined with the special requirements of the goods in terms of transport - keyword: cold chain.

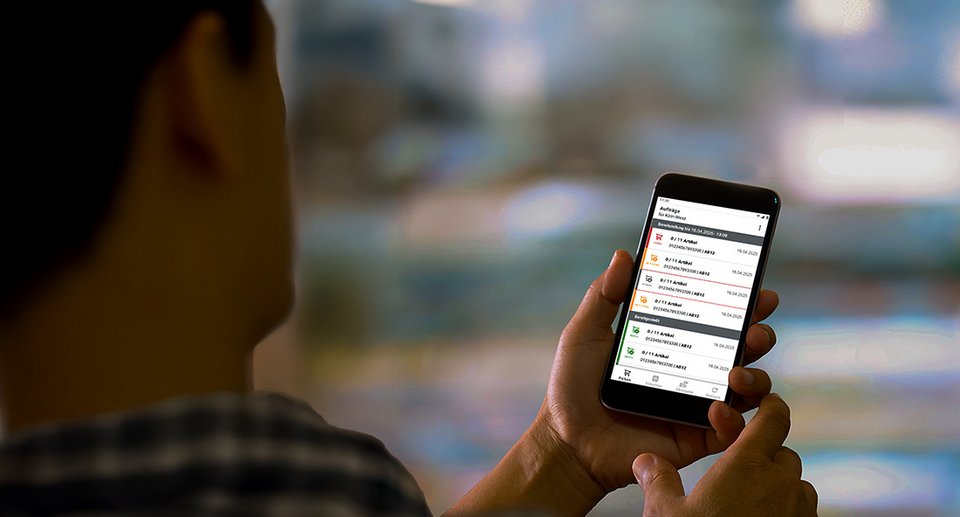

At Zabka Jush, customers order their groceries via app. From then on, time is of the essence, as the company wants to deliver the order to the customer within 15 minutes. That's why the picker in the dark store who takes the order is guided by the app so that they can put together the delivery as quickly as possible. Images of the ordered products and prices help to avoid confusion. The picker also has to scan the items. This allows the system to recognise whether the quantity of products ordered is correct. "You have to think about the employees on site and make it as easy as possible for them," says Björn Dröschel.

It took just four weeks for the Zabka Jush delivery service to go live. Now the complexity and size of the delivery area are gradually being expanded.

To ensure that there are no bottlenecks in the background with the data volumes, fulfilmenttools relies on quickly scalable cloud solutions. And in order to be as flexible as possible when connecting other systems, such as merchandise management or cash register systems, fulfilmenttools pursues a "partner first" strategy, i.e. close cooperation with system integrators, for example, who specialise in the integration of interfaces and can implement this efficiently.

With its flexible system that allows retailers to quickly integrate into the online world, fulfilmenttools has already made a name for itself in its first year. The goal for 2022 is growth, worldwide. Jürgen Brock: "Anyone looking for modern fulfilment software will find us. That's why we get enquiries from all over the world - from Germany to Canada and Australia."

What does fulfilment actually mean?

Fulfilment means "fulfilment" or "execution". In e-commerce in particular, this refers specifically to the fulfilment of a contract or order. If a customer orders a product, for example a pizza from a food supplier, the fulfilment service provider comes into play from the moment the order is placed. Everything that happens from now until delivery or even return delivery falls under the term fulfilment.

In the case of pizza, the provider first accepts the order and checks whether they can deliver the ordered goods. If this is the case, the next step is order picking, i.e. putting the order together. The selected products, in this example a vegetarian pizza and one with salami, are taken from the warehouse, the oven or a pizzeria.

The pizzas then have to be packaged and finally delivered. The pizzas are either delivered directly to the customer or the customer collects their order via the Click & Collect service.

Fulfilment usually ends when the product is handed over to the customer. The exception to this is when a customer wishes to return an order, for example an item of clothing or an electrical appliance.

It pays to keep this process under one roof. After all, only those who can harmonise all the steps can make the process more cost-effective and, not least, save resources. This ultimately leads to a competitive advantage that would not be possible without standardised fulfilment.