More recyclate in PET drinks bottles? That shouldn't really be a problem. After all, more than 90 per cent of all used bottles are collected in Germany. However, more than half of the rPET recovered from these bottles is used far away from the beverage industry. At REWE Group, we have set up a closed cycle for disposable drinks bottles on a trial basis. Our Circular Economy project creates security of supply for suppliers and helps us to achieve our recycling targets.

Food packaging fulfils important tasks. It keeps goods fresh, preserves their quality and in many cases is indispensable for transport, for example when it comes to drinks. However, packaging often quickly ends up as waste after use. That's why we at REWE Group want to make all packaging for our own-brand products more environmentally friendly by the end of 2030. How do we do this? By avoiding, reducing and improving the packaging currently in use. One approach as part of this strategy is to create closed material cycles from the company's own materials.

Take disposable PET drinks bottles, for example: The more secondary raw materials, i.e. material obtained from recycled bottles, are used in their production, the better. This is because such a cycle helps to save primary raw materials. It conserves natural resources and thus makes a positive contribution to environmental and climate protection. REWE Group has therefore set itself a clear goal: By the end of 2023, our disposable PET drinks bottles should have an average recycled content (experts refer to this as the rPET quota) of 50 per cent.

In a closed cycle to the recycling target

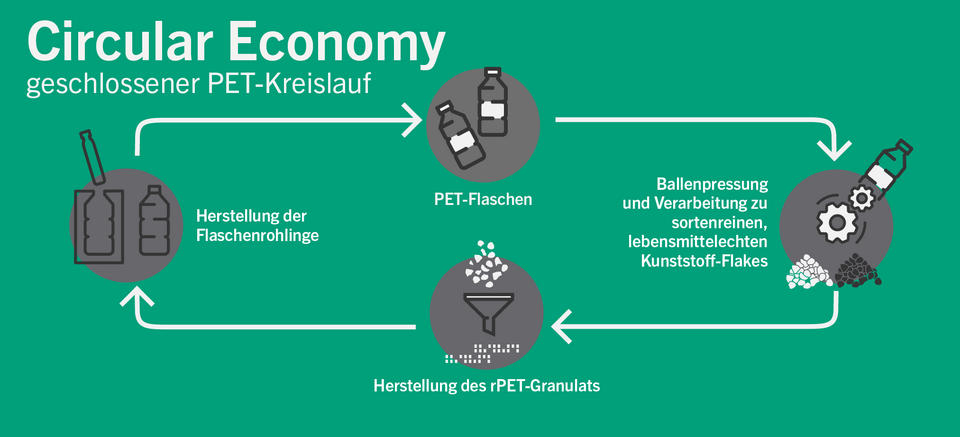

In order to safely reach this mark and to achieve even higher quotas in the following years, we have set up a closed cycle for disposable drinks bottles on a trial basis together with partners from the recycling and drinks industry. This pilot runs like this: In the first three quarters of 2023, RCS Rohstoffverwertung GmbH, a recycling specialist from Werne in North Rhine-Westphalia, will collect an agreed quantity of used bottles crushed into bales (and therefore easier to transport) from a REWE central warehouse in Cologne. RCS then recycles the PET bottles into plastic flakes - unmixed and in the colours clear and bright - and uses them to produce rPET granulate. In the next step, this recycled material is supplied to Refresco Deutschland GmbH. This is a leading bottler of soft drinks and fruit juices, including for the REWE Group. The company, which is based in Mönchengladbach, produces its own bottle blanks and can therefore use the recyclate directly. The new bottles produced with a high proportion of rPET are freshly filled and are soon back on the shelves at REWE and PENNY. A functioning closed material cycle.

Coveted raw material

© Getty Images/ lechatnoir

Why is that so special? You would think that there is enough secondary material thanks to a functioning deposit system in Germany. In fact, according to the Society for Packaging Market Research (GVM), more than 94.8 per cent of all PET beverage bottles and even 97 per cent of PET beverage bottles with a deposit (returnable and non-returnable) were reused in Germany in 2021. But this was not exclusively for the production of bottles. rPET is also a sought-after secondary raw material in other industries due to its high quality. For example, in the film industry, which uses it to produce food packaging, among other things, which cannot yet be recycled into recyclate for reuse in food applications across the board. According to the GVM, this sector accounted for almost 27 per cent of recycled PET in 2021. Other areas of application included the production of fibres and detergent bottles, plastic strapping and injection moulding applications.

© Getty Images/ lechatnoir

Why is that so special? You would think that there is enough secondary material thanks to a functioning deposit system in Germany. In fact, according to the Society for Packaging Market Research (GVM), more than 94.8 per cent of all PET beverage bottles and even 97 per cent of PET beverage bottles with a deposit (returnable and non-returnable) were reused in Germany in 2021. But this was not exclusively for the production of bottles. rPET is also a sought-after secondary raw material in other industries due to its high quality. For example, in the film industry, which uses it to produce food packaging, among other things, which cannot yet be recycled into recyclate for reuse in food applications across the board. According to the GVM, this sector accounted for almost 27 per cent of recycled PET in 2021. Other areas of application included the production of fibres and detergent bottles, plastic strapping and injection moulding applications.

We at REWE Group have now established a closed loop with our pilot. This will provide a relevant proportion of the rPET required for the beverage products of our own brands. This creates more planning security for Refresco GmbH as a producer of bottle blanks. This is because the procurement of rPET is always characterised by shortages, market fluctuations and uncertainty. According to GVM's observations, PET recycled from beverage bottles has been more expensive than virgin material for many years.

For the circular approach to succeed, it is important to work together with all stakeholders involved: with the consumers who return their empties (and thus the basic material for rPET) to the deposit machines via the deposit system, with the recyclers who process and resell the material. And with the packaging industry, which uses secondary raw materials in the production of bottles.

We consider a 50 per cent share of rPET in all single-use beverage bottles, as we want to achieve at REWE Group by the end of 2023, to be only a milestone. We want to further increase this proportion in the coming years. The establishment of a closed material cycle will play an important role in this, as it ensures the sufficient availability of suitable recyclates.

However, there are technical limits to the use of secondary raw materials in bottle production. Recycled material takes on a darker colour due to repeated heating in the production process. The better the flakes are sorted beforehand and coloured pieces are removed, the more uniform the preforms will be. If the recycled plastic blanks are not uniformly coloured, there is an increased risk of bottles bursting when inflated at high temperatures, as darker areas absorb more heat and expand faster than lighter areas. It is therefore important to sort the flakes in order to ensure that the preforms are as uniformly coloured as possible and thus increase the quality of the bottles produced.

In order for beverage bottles to retain their stability, new primary material must be fed into the material cycle time and again. Nevertheless, it is possible to produce bottles from 100 per cent recycled plastic. REWE proved this back in May 2019 when it became the first retailer to launch a private label bottle (Aqua Mia Sport, 0.75 litres) made entirely from rPET. Shortly afterwards, PENNY also added two water bottles to its range that were made from 100 per cent and 80 per cent recycled material respectively.

EU tightens the reins on rPET

The run on recyclate will increase significantly across Europe in the coming years. This is because the EU Packaging Directive adopted in 2021 stipulates a recyclate quota of 25 per cent for single-use plastic drinks bottles by 2025. In the drafts for a future EU packaging regulation published in November 2022, quotas of 30 per cent by 2030 and 65 per cent by 2040 are under discussion. In view of the 44.8 per cent rate already achieved in Germany (2021), these targets do not seem particularly ambitious at first glance. However, functioning deposit systems do not yet exist in all EU countries. These systems incentivise consumers to collect empties and return them to the cycle. The Society for Packaging Market Research expects more European countries to establish deposit systems in the near future in order to fulfil the EU requirements.

Rino Iacobellis, Senior Buyer Non-alcoholic Beverages/Beer at REWE Group Buying

Rino Iacobellis, Senior Buyer Non-alcoholic Beverages/Beer at REWE Group Buying

one: Recyclate is a sought-after raw material. What motivated REWE Group to initiate a recycling programme?

Rino Iacobellis: Recyclate has been a highly sought-after raw material since the announcement of the EU regulation that rPET must be included in drinks bottles throughout the EU in future. However, this is not enough for us at REWE Group, and we have set ourselves a much higher target of 50 per cent rPET by 2023. We therefore need the cycle to achieve our target and to support our suppliers in procuring the raw material.

one: What challenges did you face in developing the pilot cooperation?

Rino Iacobellis: The main challenge was to develop a functioning model of cooperation along the entire chain. In addition to contractual issues, we also had to re-align our purchasing and logistics processes. In the closed-loop model, we are now also involved in the supply of raw materials. For us as a retailer, this is a new form of collaboration with the supply chain.

one: The test phase is entering its second half. What are your interim conclusions? What went well, where might there be room for improvement and what will happen when the pilot ends?

Rino Iacobellis: We are currently satisfied with the progress of the pilot project and also with the cooperation with our partners. In future, we want to look at ways of expanding the model further and, if necessary, involving other suppliers. In our view, the circular economy is a topic of the future that will continue to gain in importance in view of future regulatory requirements and developments on the raw materials market.

Both German and English comments appear here.

i see a lot of potential for getting involved in the topic of reusable glass in addition to PET/plastics.