The global demand for resources for the manufacture of new products and materials has risen sharply in recent decades. This has consequences: The environment and climate are suffering from the high consumption of resources and the generation of waste. As REWE Group, we want to minimise these effects in our own value chains. As a Group, we are committed to science-based targets based on the 1.5-degree pathway of the Paris Climate Agreement. Our goal is to achieve net-zero emissions by 2050. How can we achieve this? For example, by developing measures with our suppliers on how we can use fewer resources. And, where possible, gradually returning products and raw materials to cycles at the end of their use. This is where REWE Group's circular economy experts come in, with the task of further developing the company's strategies and projects and adapting them to the increased requirements of new European legislation. Time to look back on what has been achieved and look ahead to tasks that still need to be solved.

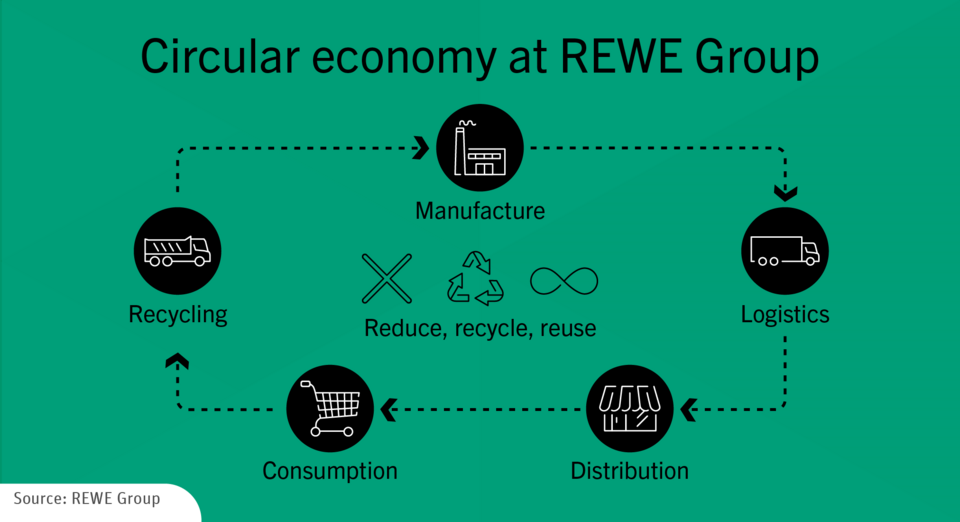

The circular economy is revolutionising the way we use resources. Instead of "take, make, throw away", it favours reuse and recycling. A win-win solution that is sustainable and makes economic sense. However, what sounds so simple at first glance presents companies with major challenges. Regulations such as the European Packaging Ordinance (PPWR) will place high demands on packaging throughout the European Union in the future. We at REWE Group also see this as an opportunity and are positioning ourselves for the future when it comes to the circular economy.

The EU wants to promote the circular economy and has drawn up a new packaging regulation (PPWR), which brings with it a great need for change for retailers and thus also for REWE Group. The law aims to reduce packaging waste and promote the reuse and recycling of packaging. The PPWR came into force on 11 February. The first regulations will be binding for everyone from August 2026.

- new EU regulation for standardised regulation of packaging and packaging waste in all EU countries

- affects packaging manufacturers, industry and trade

- Recycling is to be promoted and non-recyclable packaging is to be banned

- requires minimum percentages of recycled material in plastic packaging

- sets binding reusable quotas, e.g. for beverage packaging

- defines future restrictions and bans for certain single-use packaging

At the REWE Group, we addressed the new requirements of the PPWR at an early stage in order to be able to react to the changes in good time. We see this as an opportunity to make our packaging recyclable and further improve our ecological footprint.

At the same time, it is essential that the EU Commission starts drafting and publishing delegated acts and guidelines as soon as possible, as the technical details are crucial for practical implementation in companies. We would like to see transparent drafting with the involvement of the relevant stakeholders and experts.

Building on our strategy, which was adopted in 2019 and has been continuously developed since then, we want to further reduce the environmental impact of packaging in line with the principles of "Avoid, Reduce, Improve". We have set ourselves the goal of making 100 per cent of all own-brand packaging at REWE, PENNY and toom Baumarkt DIY stores in Germany and BILLA, BILLA PLUS, PENNY and ADEG in Austria more environmentally friendly by the end of 2030. To this end, we have defined sub-targets in the strategy for the REWE and PENNY product ranges in Germany, for example on the topics of reusable packaging, the use of recyclates and recyclability. The 'More environmentally friendly packaging' guideline sets out the do's and don'ts when designing packaging.

In addition, we have developed a circular economy strategy for 2021, which also covers products and raw material cycles in our supply chains in general.

Recyclables management plays an important role in the development of closed-loop systems. At REWE Group, the team led by Lara-Christina Sell, Head of Indirect Spend, and Wassilij Weber, Head of Recyclables Management, has been working since 2024 on the question of how we can utilise our recyclable materials for as long as possible. The team is initially focussing on the German market and the private label products offered there.

(C) Getty Images: Naruecha Jenthaisong

Recyclable materials are waste whose components or residual materials can be reused through recycling - in converted form or broken down as a raw material. Recyclable materials include PET bottles, paper, cardboard and film, for example.

(C) Getty Images: Naruecha Jenthaisong

Recyclable materials are waste whose components or residual materials can be reused through recycling - in converted form or broken down as a raw material. Recyclable materials include PET bottles, paper, cardboard and film, for example.

Wassilij Weber and his team of experts have set themselves the task of transferring recyclable materials into cycles. To this end, the recyclables management team maintains a network of recycling companies that process the recyclable materials into so-called recyclates. These recyclates can then be used as more environmentally friendly packaging materials, which can also reduce costs in the long term.

REWE Group has been implementing a pilot project for several years now: a closed cycle for disposable drinks bottles. The idea: Empty PET bottles handed in by customers in the stores ("one-way deposit") are consolidated in the REWE and PENNY warehouses. There, the PET material is pressed into bales. The PET bales are processed into a PET recyclate by specialised recyclers and ultimately reused in the PET bottles of own-brand beverages. This will enable us to increase the proportion of recyclate in our own-brand PET single-use beverage bottles to 50% on average from 2023. One of the key plans of the recycling management team is to build on this pilot project and, in collaboration with those involved in the supply chain, to establish further cycles for other recyclable materials.

According to the PPWR, recyclate quotas of 10-35% are prescribed for various areas of application in plastic packaging by 2030. "In order to be able to guarantee the supply of the required recyclates for our own-brand packaging in the future, it makes sense to think in cycles. In closed loops, retailers will not only be buyers of retail products in the future, but also suppliers of important recyclable materials," says Wassilij Weber. In view of the large quantities of recyclable materials and the complexity of the supply structures, it is therefore also important to establish an infrastructure for the targeted recycling of recyclable materials. To this end, we want to establish partnerships with recyclers and suppliers in order to better secure the supply of raw materials in the supply chain.

(C) Getty Images: Olga Pankova

(C) Getty Images: Olga Pankova

The cycle of tomorrow

We at REWE Group have already achieved a great deal in the area of packaging and recycling, but we still have some tasks to solve together. We are not alone in this: the circular economy is also a cultural change that must be supported by all parts of society. Consumers play a key role by making conscious choices in favour of environmentally friendly products. Political actors can provide directional support through promotion and regulation, paving the way for a sustainable future. By closing loops and conserving resources in a cycle of use and recovery, we can help to reduce the burden on the planet in the long term.

Pia Schmueck

one: Why is the circular economy so important for REWE Group?

Pia Schmueck

one: Why is the circular economy so important for REWE Group?

Pia Schnück: The circular economy is often described as the economic model of the future. It promises a win-win situation. On the one hand, the circular economy can make a significant contribution to conserving resources and protecting the climate, while at the same time it promises potential for value creation. The circular economy can therefore not only contribute to achieving our SBTI climate targets. For us as REWE, it also gives us the opportunity to secure access to materials or resources and even cushion price risks if necessary.

one: What changes will the PPWR bring for retailers in the future in terms of formulating packaging strategies and managing packaging requirements?

Pia Schnück: The PPWR turns many topics that retailers have already anchored in their sustainability strategies into binding requirements. On the one hand, this offers opportunities: for example, it creates a level playing field when it comes to recyclability. The fact that all packaging is to be recyclable according to a uniform European standard in future means that there will be more commitment and predictability in the future than if individual companies set themselves individual targets.

On the other hand, the content requirements of the PPWR are very demanding. In the area of recyclate use in food packaging, for example, suitable solutions for various product ranges will first have to be developed in some cases over the coming years. The comprehensive, process-related control and fulfilment of the many requirements will also be a major operational task for retailers and manufacturers in the coming years.

in terms of sustainability strategies, companies will be faced with the question of which focal points and innovations they can use to impress customers beyond the minimum legal requirements and generate additional impact in the future. We believe that our existing strategy forms a good basis here and will continue to develop it over the coming years.

Lara-Christina Sell

one: What are the major challenges that the team is dealing with?

Lara-Christina Sell

one: What are the major challenges that the team is dealing with?

Lara-Christina Sell: Recyclables management focuses on maximising the amount of recyclable materials that can be reused. This pursues several goals at the same time: In addition to aspects of Sustainability, we also see this as an opportunity to work with and for our suppliers to establish a secure supply of recyclates, among other things to fulfil the PPWR, but also to have greater control of our own over recyclables, value-added stages of packaging and thus also costs.

Establishing these recycling concepts requires the efforts of many stakeholders. The recyclables management team must not only network closely with suppliers, but also consider many aspects within REWE Group: purchasing, sales department and logistics processes must be taken into account, legal and accounting aspects must be considered and the development of raw material prices must be kept in mind. Ultimately, of course, we want and need to remain monetarily competitive.

The concepts must then be implemented operationally so that we can also realise the potential. We therefore have experts in the recyclables management team who drive these topics forward with expertise from the waste management industry and REWE Group's internal knowledge.

one: What do you want to achieve in 2025 and over the next few years?

Lara-Christina Sell: Our goal for this year is to cover further parts of our rPET requirements for mineral water and carbonated drinks from our own recyclable materials. This will require a significant expansion of our partner network as well as some customised processes. At the same time, we are already thinking ahead and have our sights set on the next recyclable materials, such as films and cardboard packaging, and are in close dialogue with private label and non-commercial goods buyers to determine which other products could be suitable for recycling.

Vasily Weber

one:Why is cooperation with the supply chain in the supply of raw materials becoming increasingly important for retailers? How do we want to position ourselves as REWE Group?

Vasily Weber

one:Why is cooperation with the supply chain in the supply of raw materials becoming increasingly important for retailers? How do we want to position ourselves as REWE Group?

Wassilij Weber: We assume that raw materials and recyclates will become increasingly scarce, not least due to EU-wide regulation. We need to be prepared for this scenario and secure or expand our access to valuable recyclates. Where we do not cover the various stages of the value chain ourselves (as some of our competitors do), we organise the cycles together with various partners in order to position ourselves as REWE Group in the best possible way for the future.

one: What role does recyclables management in particular play in the circular economy?

Wassilij Weber: Incorporating the recyclable materials generated in REWE Group's warehouse logistics into the packaging of tomorrow is a complex process with many players involved. The demands on material qualities and technical requirements should not be underestimated. After all, not all plastics are the same! That's why it makes sense for these processes to be set up and operationally managed by a team with in-depth industry experience.

one: Are there any initial successes?

Wassilij Weber: We are currently in the immediate preparation phase for various pilot material cycles. These include projects to recycle films from our warehouses. We expect these tests to provide us with important insights that will enable us to roll out the relevant material cycles further in the next stage.

In addition, we were also able to combine packaging licensing with our partner, the Dual System, with concepts for establishing material cycles. We see this as a key lever for sustainable packaging design through the use of plastic recyclates.

Dr Jens Emsinghoff

one:What is the importance of REWE Group's legal department in the management of recyclable materials?

Dr Jens Emsinghoff

one:What is the importance of REWE Group's legal department in the management of recyclable materials?

Dr Jens Emsinghoff : The new recycling projects are particularly interesting and important for REWE Group in the long term. This is because it gives us access to increasingly sought-after recyclable materials on the market, which we need in order to achieve our sustainability goals and at the same time gain legal access to production-relevant recyclable materials. In this way, we also create price stability and supplier loyalty. We have been involved in drafting contracts for the projects since the very beginning. We started with a small pilot for the PET cycle. We were able to successfully negotiate and implement this so that it could be expanded. We now have the opportunity to apply the legal experience we have gained to other recycling projects, where we use sophisticated legal structures to maximise transparency in pricing and raw material availability. Dr Vanessa Farmand's team also closely monitors these contractual arrangements from an antitrust law perspective. Together with the recyclables management team, we have successfully familiarised ourselves with a new field of contract design and can provide our colleagues with pragmatic advice and support. It is fun to combine sustainability goals with profitability and thus help the company continue to succeed and grow.